Full ground up restorations developed by years of experience of our founders which starts with the meticulous removal and cataloging of the rare original parts of each project car and carefully stored for restoration of as many parts as possible to be reused as we firmly believe in maintaining the originality of each and every car . From the restorative panel work by skilled old school artisans to the final mechanical rebuild of the plethora of components with introduction of modern day finishes to the final assembly and trimming of the interior tailored from templates drafted from the originals , every detail is of the most importance to us in the pursuit of the final experience of the driver in his cockpit of a car saved from oblivion and restored in very sense of the word.

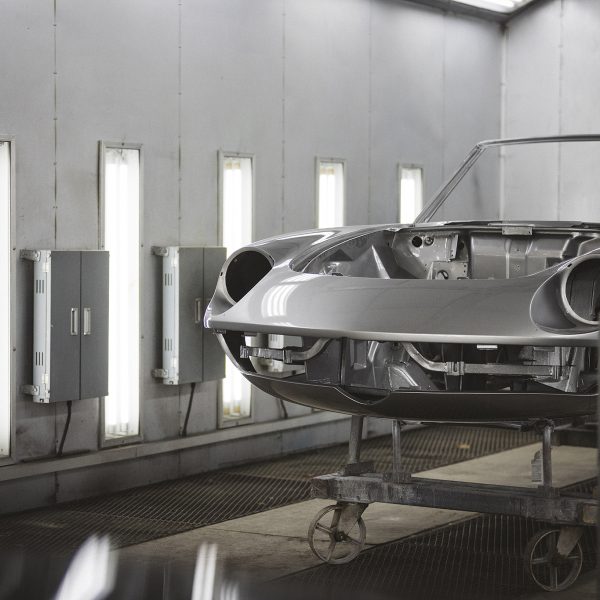

Combining the almost lost age old skills of panel beating and new replacement parts depending on the level of restoration is required determined when a careful assessment is made during each intake . We understand that each individual project with its’ own unique needs as every car is indeed different and in the aim of maintaining originality , we strive to use bespoke panels tailor made for each car by means of letting in repair sections and when deemed necessary , full replacement of panels where structural integrity is lost or panels are overly distorted and abused over years of bad repairs beyond repair.

The process starts immediately after the car has been stripped of all mechanical components, body trim and interior trim when the sympathetic stripping of old paint and putty is achieved by a media blasting process and a coating of etch primer is immediately applied to protect and sustain the bare body against rust during the period of the restoration process.

A most crucial process after hundreds of hours spent on the restoration of the chassis and panels .

Leaving no stone unturned in a highly labour intensive process of hand stripping the restored body shell back to bare metal again before high grade epoxy primer is applied thoroughly in every crevice and corner before the preparation process begins to sculpt each and every car by our skilled artisans which is today another lost trade.

Owners can then select from a wide range of original colours from our archives with colour sample comparisons to actual factory colour samples for the utmost accuracy and only a comprehensive range of PPG system refinishing products are used throughout the whole process at every stage to maintain integrity and to avoid any contamination from sub standard products.

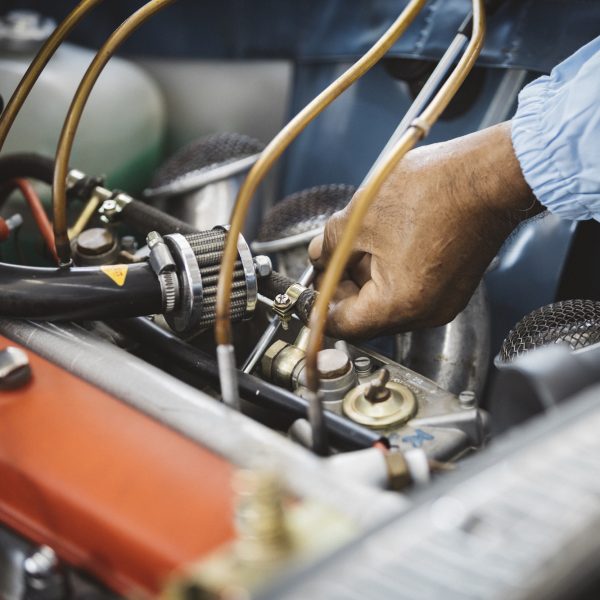

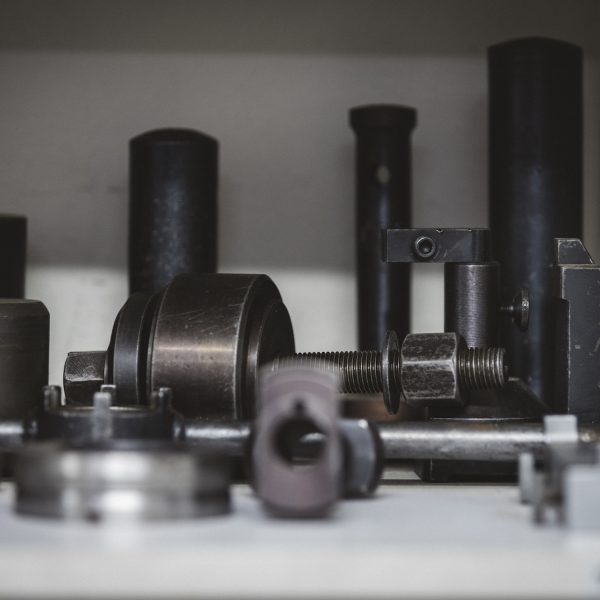

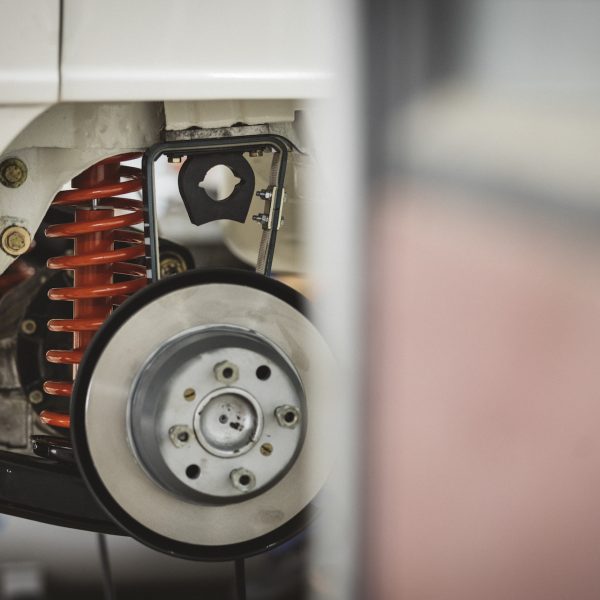

Rebuilding in every sense of the word, every reusable component is carefully inspected again for damage before suitable methods comprising of media blasting ,vapour blasting and hand polishing processes to breathe a new life into all the selected components.

High quality parts from our parts department are then used to replace all serviceable and replaceable parts for every mechanical rebuild. Literally a nuts and bolts restoration where every single piece of hardware is hand polished before the re plating process.

Jealously guarded factory original tools are used in the recommended manner to have precisely fitted parts during the re assembly process of the undercarriage and other mechanical components.

Body trim that has been meticulously restored and re plated now earns its place back into the newly refinished body shell and precious New Old Stock parts from our department is then lovingly and carefully installed whilst all rubber seals and parts are completely replaced and the car goes through a water testing process rule out any potential leakages and all shut lines thoroughly checked for perfection .

Door furniture are completely replaced and irreplaceable items tediously restored and re plated before reinstatement into the cockpit .Instruments and gauges are also revived and reassembled after careful cleaning and regulators and control assemblies are taken apart before every part is restored and reassembled to ensure smooth operation whilst a special department rebuilds or fabricates rare and unavailable parts to replicate anything from missing glovebox covers to ashtrays.

At the end of every restoration project comes the most satisfying part to restore the interior to its resplendent glory after years of use. Seats and other trim are carefully tailored from original templates and stitched in bespoke fashion after the frames are completely rebuilt and refinished and the squabs itself resculpted with new foam and padding before retrimming in either original vinyl of the period or popular upgrades to specially tanned leather emulating the original trims available then.

Upon final completion with restored instruments , newly installed lighting , rare New Old Stock rare parts and the distinctive aroma of a newly trimmed interior the cockpit exudes an incomparable welcome for its driver to be ensconced back in the environs he once knew so well and now fully rejunevated marking the end of an enjoyable journey in readiness for the real journey on the roads.